What is Nitrile?

Nitrile, or BunaN, is a copolymer of butadiene and acrylonitrile. It is a general purpose oil resistant polymer.

Nitrile has a typical service temperature range between –40° F and +275° F.

ADVANTAGES:

Nitrile has excellent resistance to oil, gasoline, solvents, mineral and vegetable oils, hydraulic fluid, and fuels. It is recommended for applications that require good oil and grease resistance as well as moderate ozone resistance. With compounding, it is possible to get a fairly good balance between low creep, good resilience, low permanent set and good abrasion resistance. Nitrile is superior to most elastomers with regard to compression set or cold flow, tear and abrasion resistance. Nitrile resists acids and bases with the exception of those having strong oxidizing effects. Nitrile is resistant to a broader range of aromatic hydrocarbons than neoprene. Resistance to heat aging is good.

LIMITATIONS:

Nitrile has poor resistance to ketones, chlorinated hydrocarbons, and nitro hydrocarbons. It does not have good ozone, oxygen or sunlight resistance without the addition of special additives. Nitrile’s low temperature resistance is inferior to natural rubber, and although nitrile can be compounded to give improved performance in this area, the gain is normally at the expense of oil and solvent resistance. Conversely, with higher acrylonitrile contents, the solvent resistance is increased but low temperature flexibility is decreased. Nitrile, like SBR, does not crystallize on stretching. Thus, reinforcing materials, such as carbon blacks, are required to obtain high strength. Tear resistance is inferior to that of natural rubber and electrical insulation is lower.

COMMON APPLICATIONS:

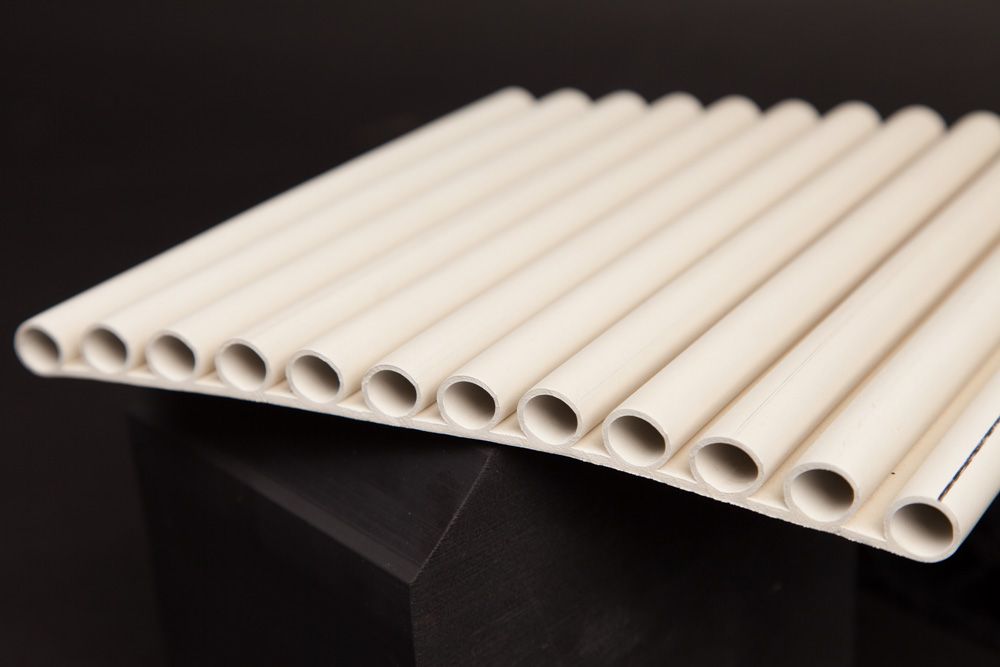

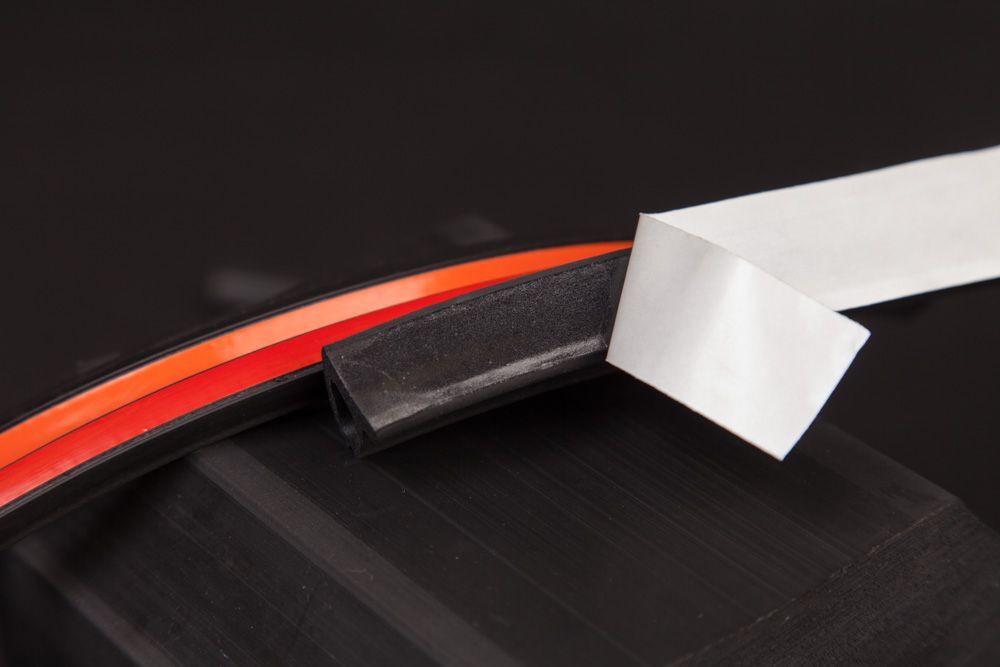

Nitrile is recommended when excellent resistance to petroleum oils, gasoline, and/or greases is needed. Nitrile is the most widely used elastomer for sealing products due to its excellent resistance to petroleum products and its wide temperature range. More than 50% of the o rings sold are nitrile o rings. Nitrile is also widely used with hydraulic fluid and alcohol applications. Nitrile is commonly used for industrial and automotive applications, in products such as fuel and oil handling hoses, petroleum oil seals, grommets, hydraulic hoses, hydraulic fluid seals, transmission fluid seals, rollers, shock and vibration mounts, and o rings. Typical applications of the premium grades of NBR include carburetor gaskets, fuel pumps, diaphragms and aircraft hose gaskets. The commercial grades of NBR are usually blends of NBR with other polymers. These less costly blends accommodate less demanding applications where oils and heat are prevalent. Ozone resistant nitriles are recommended where extended exposure to air and ozone is anticipated.

Slide title

Write your caption hereButton

Durometer

The hardness of rubber compounds is measured by the Shore A durometer; the higher the durometer number, the harder the compound. Softer compounds stretch easier and seal better on rough surfaces. Harder compounds offer greater abrasion/extrusion resistance.

Typical Questions Asked

- What is the application or function of the part?

- Is there a target cost per part that should be considered?

- Will the part be located inside or outside?

- What, if any, are the temperature requirements?

- Is there exposure to specific chemicals?

- Does the part need to meet any regulatory requirements?

Now that you know what materials your project needs, fill out a request for a quote form to get started.

For more detailed information on material selection, please see our engineering technical information page. Several PDF data sheets are available for download.

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

-

CUSTOM ON-SITE TOOLING

Learn more →We meet your needs for custom extrusions with in-house, custom tool and die design services.

-

TECHNICAL RESOURCES

Learn more →Find technical resources and to assist in the design of effective and efficient rubber extrusions.

-

DESIGN ASSISTANCE

Learn more →We're ready to offer design assistance and troubleshoot old problems for your unique project.

-

MATERIAL SELECTION

Learn more →Control the cost of your product without sacrificing performance with smart materials selection.

Request a Quote

And we’ll get right back to you.

Sign up to our newsletter

We will get back to you as soon as possible

Please try again later

Want more information?

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

ELBEX CORP

Get In Touch

Phone: 330.673.3233

Fax: 330.673.3235

Email:

info@elbex-us.com

Address: 300 Martinel Dr. Kent, OH 44240

Latest news