We Make Custom Rubber Extrusions.

ELBEX Corporation, one of the leading rubber extrusions manufacturers, is an ISO Certified leader in custom rubber extrusions and silicone extrusions.

Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials.

WE ARE ELBEX

ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials. Commonly used rubber extrusion materials include Silicone, EPDM, Polyisoprene, Neoprene, Nitrile, Butyl, SBR and Natural Rubber. We currently serve various industries such as automotive, mass-transit/railway, architectural/construction, water control, container, pipe, and appliance gaskets as well as many others.

Custom Rubber Extrusions for a Range of Industries Including:

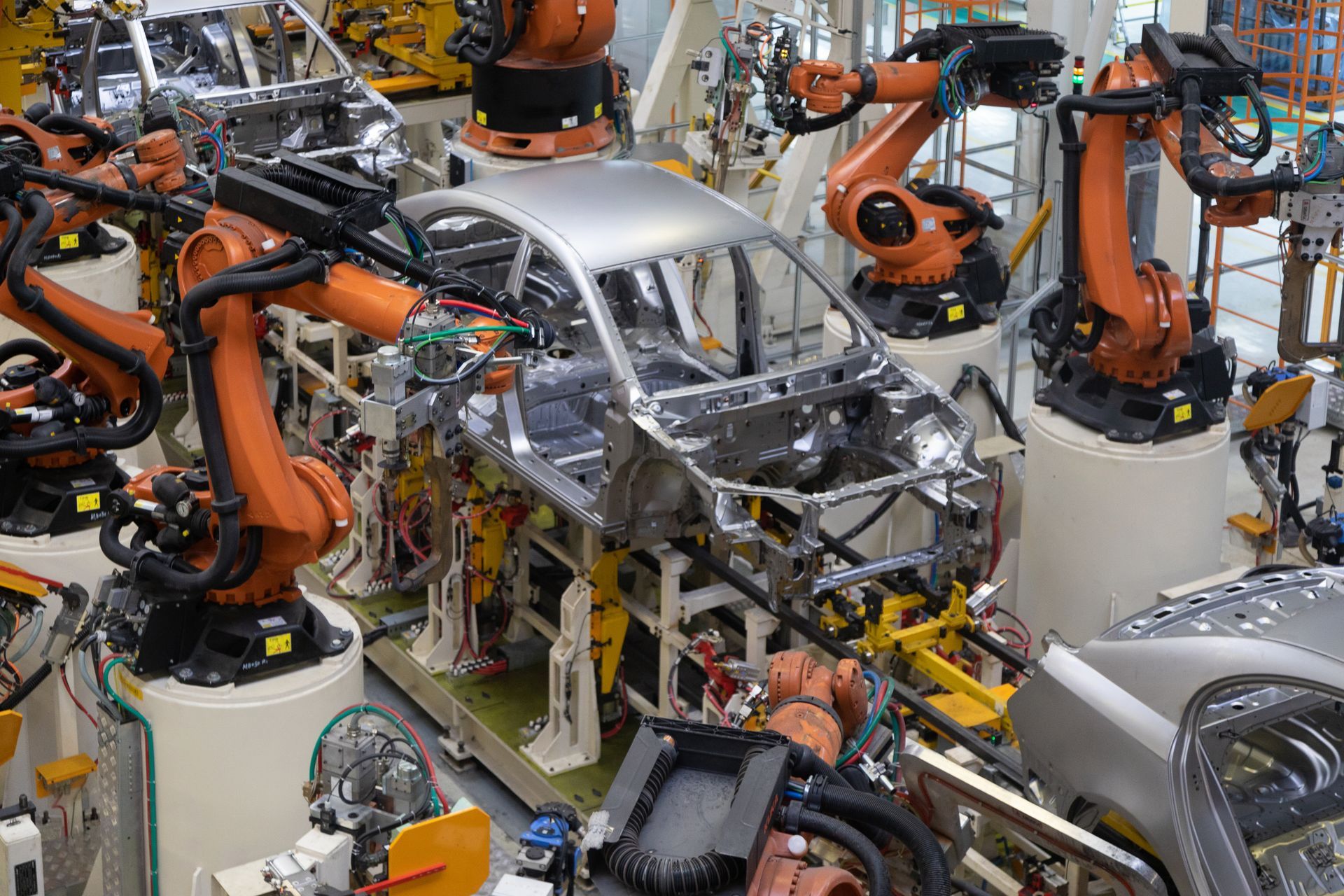

Automotive

We serve the automotive industry with custom rubber extrusions.

Construction & Architectural

We serve the construction industry with custom rubber extrusions.

Water Control

We serve the water control industry with custom rubber extrusions.

Mass Transit & Railway

We serve the mass transit industry with custom rubber extrusions.

We commonly use a variety of materials to create our extrusion profiles including Silicone, EPDM, Polyisoprene, Neoprene, Nitrile, Butyl, SBR and Natural Rubber. As a result, ELBEX has the experience to serve a wide range of industries such as automotive, mass-transit/railway, architectural/construction, water control, container, pipe, and appliance gaskets as well as many others.

Trust is the Foundation of Outstanding Service

Over the years, ELBEX Corporation has developed very strong partnerships with vendors and suppliers in order to meet and exceed customer expectations. To minimize lead-time and reduce cost, ELBEX is able to provide many value-added services, such as in-house die tooling, on-site silicone mixing, and silicone color matching, as well as printing, cutting, splicing, and taping. ELBEX also maintains a 100,000 pound capacity cold room to inventory compounds for production, which gives us the flexibly to deliver a quality product with shorter lead times.

| Why Our Customers Love Us | |

|---|---|

| ✓ In-House Die Tooling | ✓ Broad Expertise |

| ✓ On-Site Silicone Mixing | ✓ ISO Certified |

| ✓ Printing, Splicing, & Taping | ✓ Color Matching |

ELBEX News