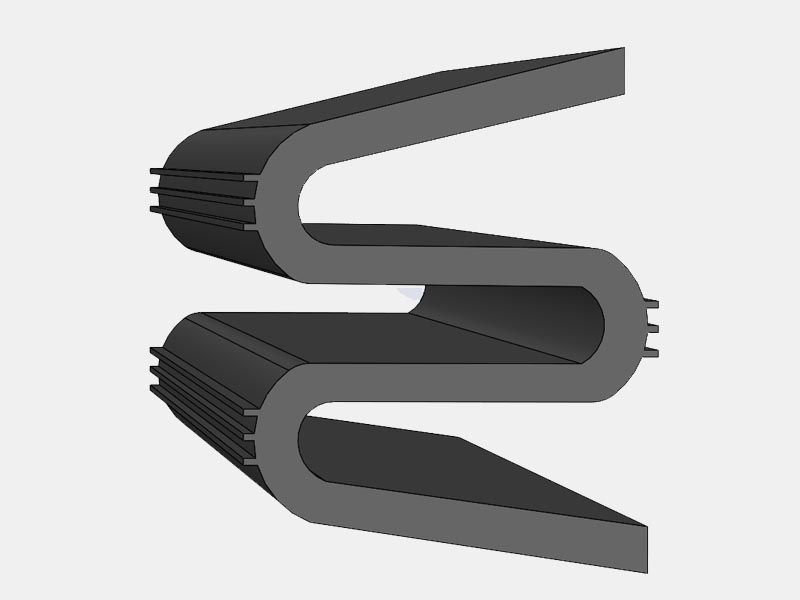

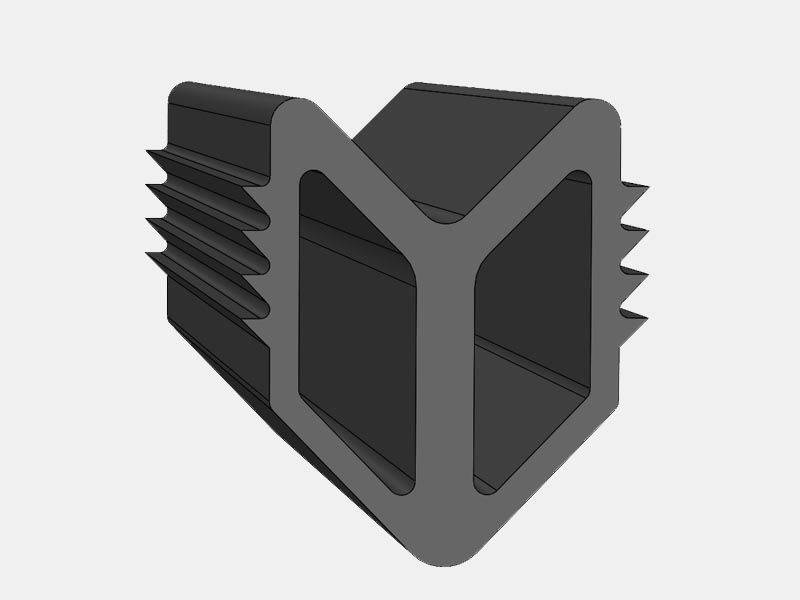

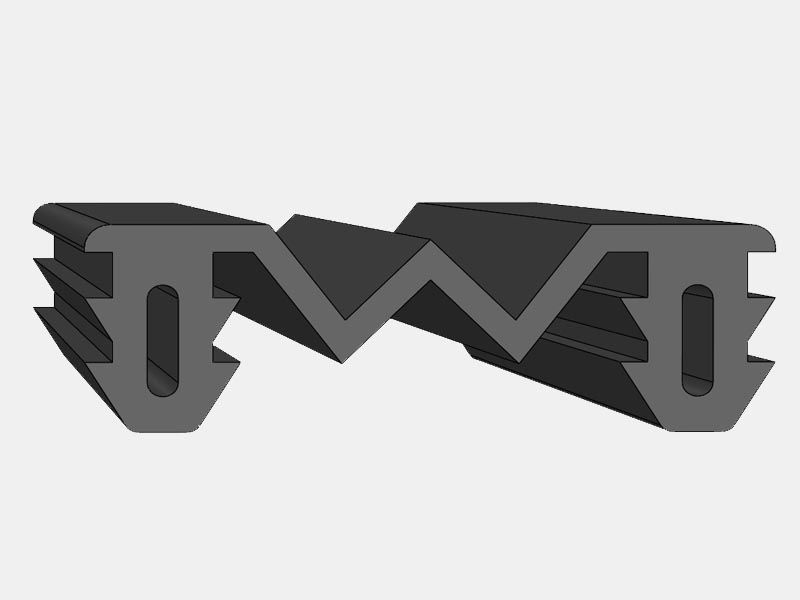

Extruded Rubber Expansion Joints

Expansion joints are used in a variety of applications, but are most commonly used in industrial piping systems or in situations where there’s a need to reduce movement and vibration—any time there is concern of structural damage due to the expansion or contraction of those surfaces. Extruded rubber expansion joints from ELBEX provide superior stability and protection compared to other types of expansion joints because of our team that’s dedicated to quality through the entire extrusion manufacturing process.

Expansion Joint Applications

Extruded rubber expansion joints are most commonly used in the following industries:

- Manufacturing - The most common application of expansion joints is in industrial piping systems where they’re used as a transition between two surfaces. They are also often used as outgassing expansion joints in clean room ductwork.

- Construction - Expansion joints are also referred to as movement joints because of their ability to keep structures held in place. They are commonly used in architecture and construction to relieve stress on building materials caused by natural expansion and contraction or by seismic activity.

Because of the versatility of our extruded rubber profiles, they can be used as a viable solution in so many different industries and applications. Our design and engineering team can assist you in finding the right extrusion to meet your needs. Please contact us to discuss your specific application needs.

Custom Expansion Joint Design and Value-Added Services

In addition to designing and engineering custom extrusions, we are able to provide many value-added services, such as in-house die tooling, on-site silicone mixing, and silicone color matching, as well as printing, cutting, splicing, and taping.

We take pride in our ability to deliver custom-manufactured movement joints to meet your specification requirements.

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

CUSTOM ON-SITE TOOLING

We meet our customers’ needs for unique custom extrusions with in-house, custom tool and die design services.

TECHNICAL RESOURCES

We offer several technical resources and PDFs to assist in the design of effective and efficient rubber extrusions.

DESIGN ASSISTANCE

We offer cost effective solutions by achieving the proper performance levels with smart materials selection.

Applications in the Manufacturing Industry

Our rubber extrusions play a vital role in the performance of a wide range of industrial and manufacturing systems. Our products can be manufactured to withstand extreme environments that manufacturing and industrial environments are subject to, including direct sunlight and dramatic changes in temperature that can cause expansion and contraction. Whether you need a rubber extrusion for a specific product you’re manufacturing, or for the actual factory building itself, our rubber extrusions fit the bill.

- Pipe ramps

- Glazing system profiles

- Silicone sheeting

- Expansion joints

Applications in the Construction Industry

ELBEX can offer high quality, custom rubber extrusions to the construction industry to help maintain structural integrity. Our engineers will work with you to find the right solution for your project, and choose materials that meet regulatory standards and building codes. Our rubber extrusions are most commonly used in the construction industry as environmental barriers, to fill voids between two surfaces, and to ensure a proper fit. Our rubber extrusions play a vital role in the structural integrity of buildings and other structures. Our products can be manufactured to withstand extreme environments that buildings are subject to, including direct sunlight and dramatic changes in temperature that can cause expansion and contraction.

- Weatherstripping

- Glazing

- Edge trim

- Door and window seals

- Expansion joints