Custom Extrusions for the

Construction Industry

ELBEX offers high quality, custom, rubber extrusions for the construction industry to help maintain structural integrity, provide an environmental barrier, to fill voids between two surfaces, and to ensure a proper fit. Our engineers will work with your industry professionals to find the right solution for your project, and choose materials that meet regulatory standards and building codes. Contact us today to let us know what your project requires!

Applications in the Construction Industry

Our rubber extrusions play a vital role in the structural integrity of buildings and other structures. Our products can be manufactured to withstand extreme environments that buildings are subject to, including direct sunlight and dramatic changes in temperature that can cause expansion and contraction. Some of these solutions include:

- Weatherstripping

- Glazing

- Edge trim

- Door and window seals

- Expansion joints

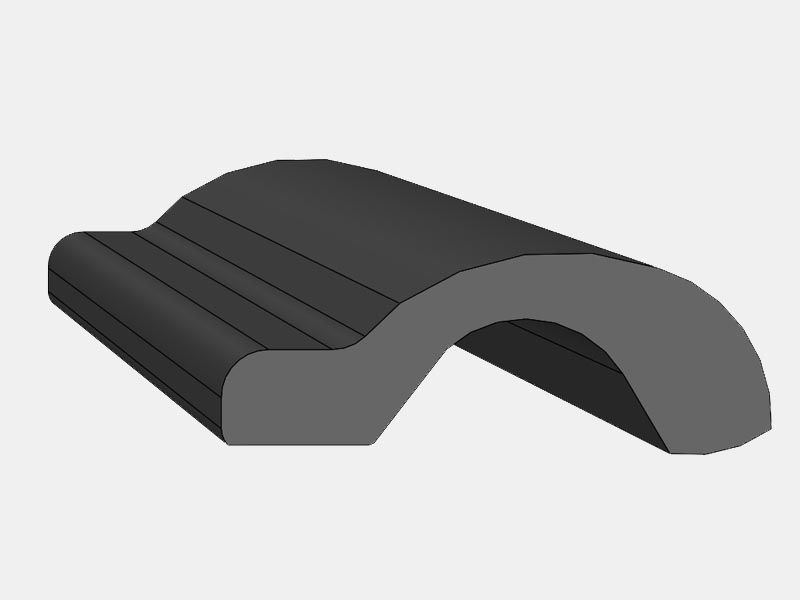

Extruded Rubber Expansion Joints

Expansion joints are used in a variety of applications, but are most commonly used in industrial piping systems or in situations where there’s a need to reduce movement and vibration—any time there is concern of structural damage due to the expansion or contraction of those surfaces.

Extruded rubber expansion joints from ELBEX provide superior stability and protection compared to other types of expansion joints because of our team that’s dedicated to quality through the entire extrusion manufacturing process.

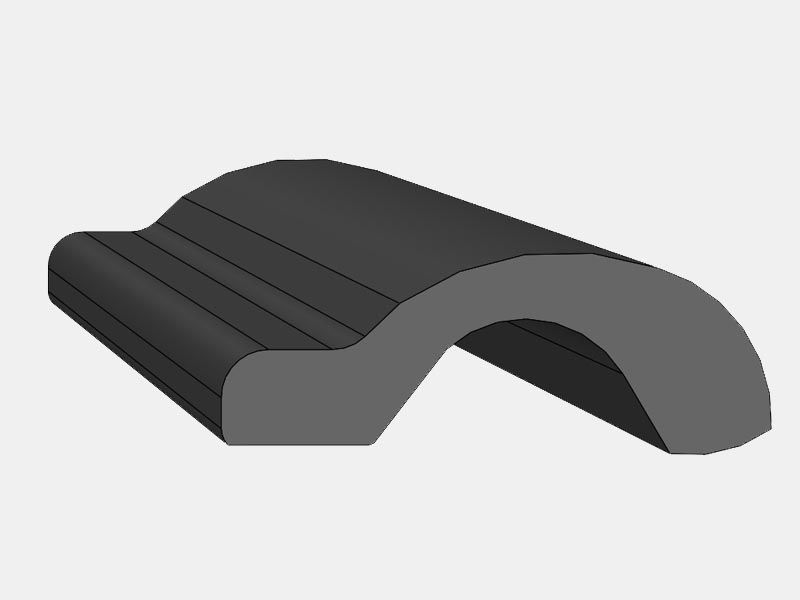

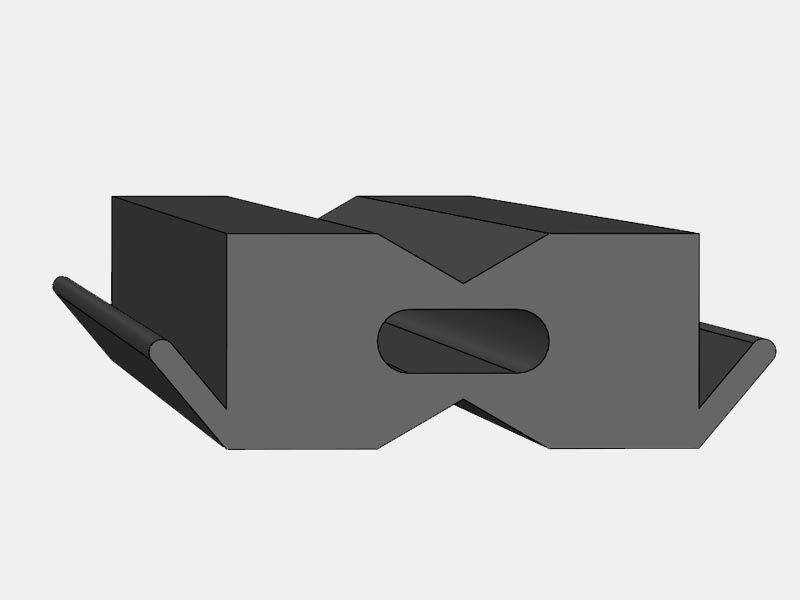

Extruded Rubber Gaskets and Seals

Gaskets and seals are very general terms for any type of profile that is intended to fill a gap or void and create a barrier. Both gaskets and seals are commonly used for:

- Water resistance

- Air barriers

- Tight seals

- Vibration elimination

- Securing components

Gaskets and seals are often lumped together into the same category because they both provide a strong sealing force, but their functions are slightly different. Seals are used to connect and seal two moving parts, while gaskets are commonly used as static seals between two flat surfaces set in place. Materials used for either product vary, but are often dictated by the specific application and corresponding environmental and chemical exposure.

Extruded rubber gaskets and seals from ELBEX provide superior stability and protection compared to other types of expansion joints because of our team that’s dedicated to quality through the entire extrusion manufacturing process.

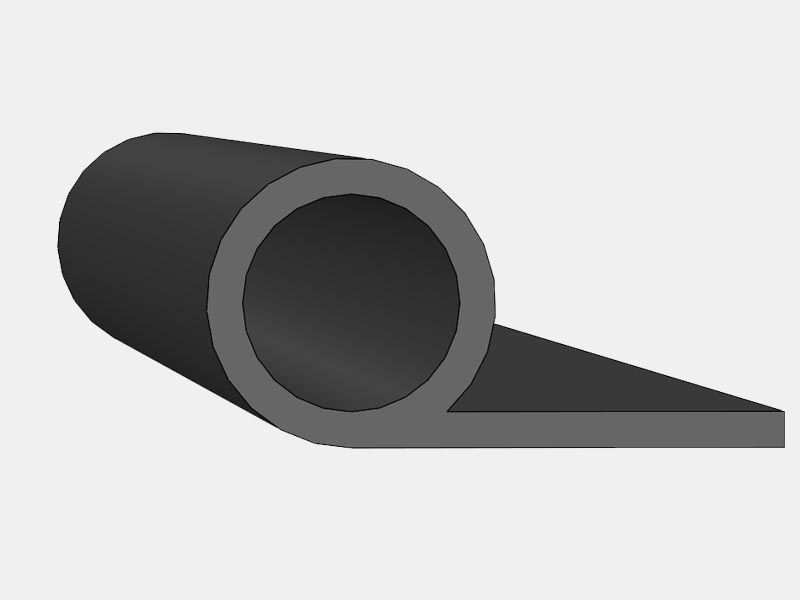

Custom Extruded Rubber

Pipe Seals & Ramps

- Construction - Construction sites are prone to having exposed pipes, cables, hose, or electric conduit lines that can be damaged by load-bearing traffic. These ramps and seals are used to help mitigate damage to existing and new pipe systems that could result in leaks while on site and thereafter. Having these in place during construction is an essential part of being able to stick to the scheduled timelines you’ve mapped out with your customers, and prevent leakage headaches - that can eat away at your margins and reputation.

- Industrial/Manufacturing - In this world of many moving parts and use of heavy machinery, knowing you have sound structural and material integrity in all areas of your building is crucial. Using pipe seals and ramps throughout your facility adds a strong and durable buffer between ever-moving objects and stationary piping, preventing potential punctures and bursts of pipes under pressure or containing fluids.

- Infrastructure - Oftentimes infrastructure cabling is encased and placed underground, buried beneath feet of dirt and rocks. The cabling and casing are usually provided by the same business, and graded for weight and weather resistance. Using pipe seals in these applications can significantly boost protection of these critical components.

- Oil and Gas - Anytime piping is going underwater, those pipes are exposed to the adversity of activity the ocean throws at them. Protecting these pipes with the proper seals can prevent natural and man-made debri from causing direct impact or abrasion.

Please contact us to discuss your specific application needs.

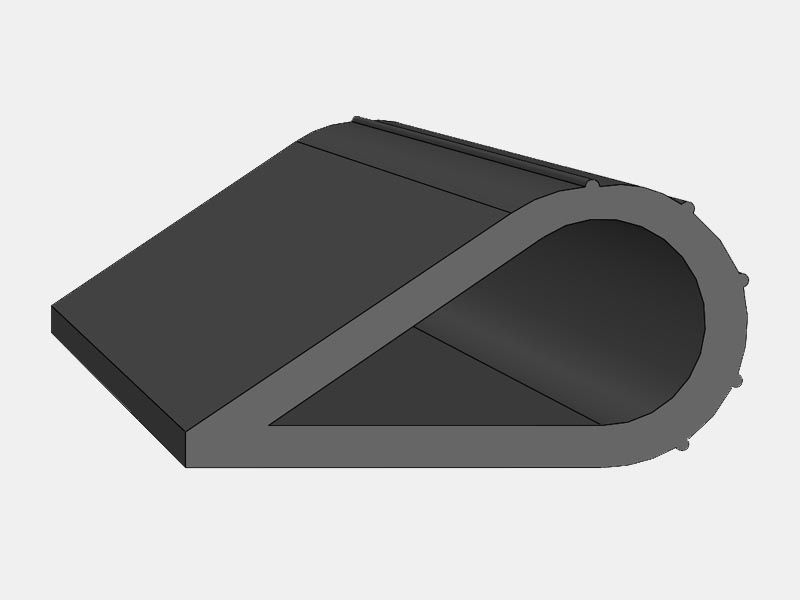

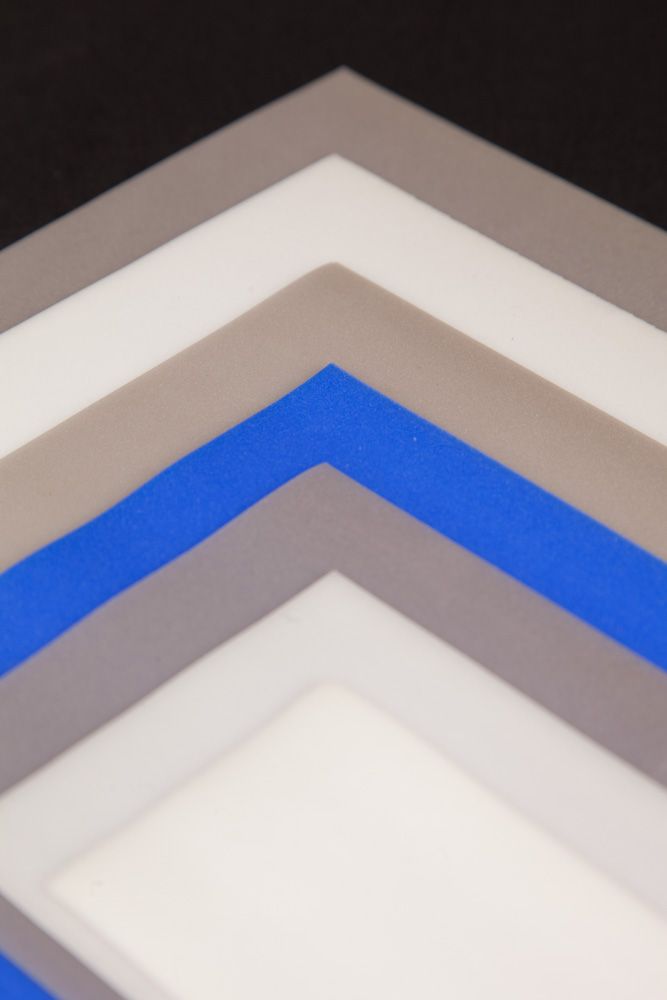

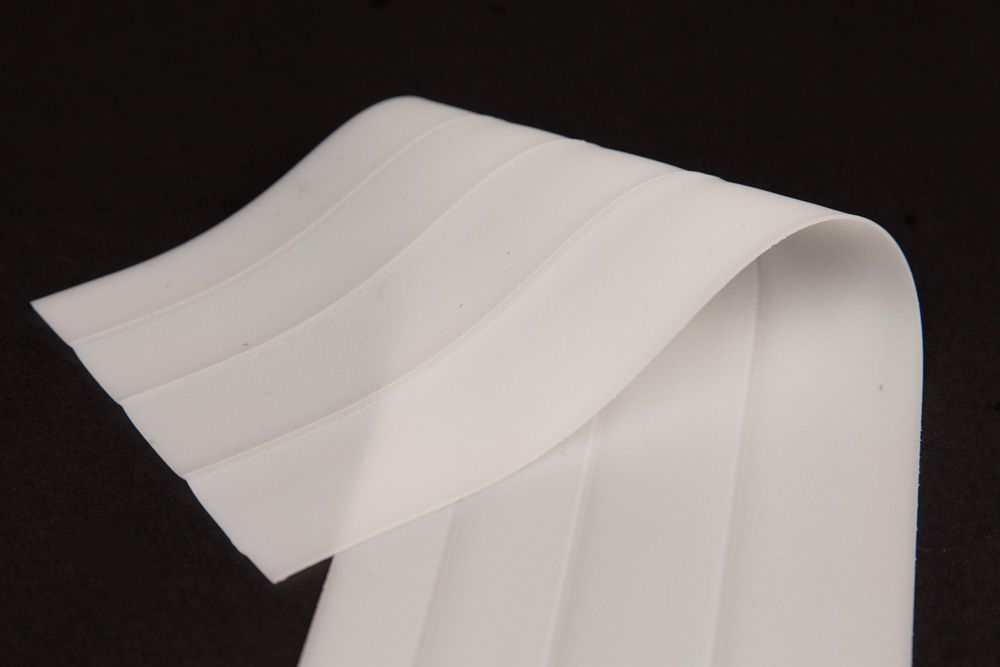

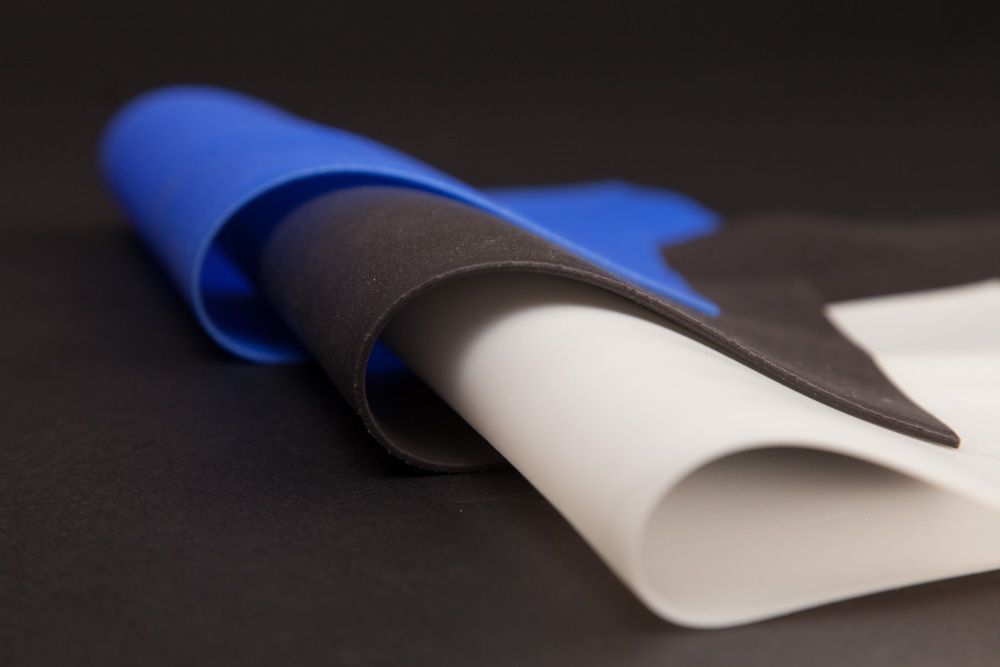

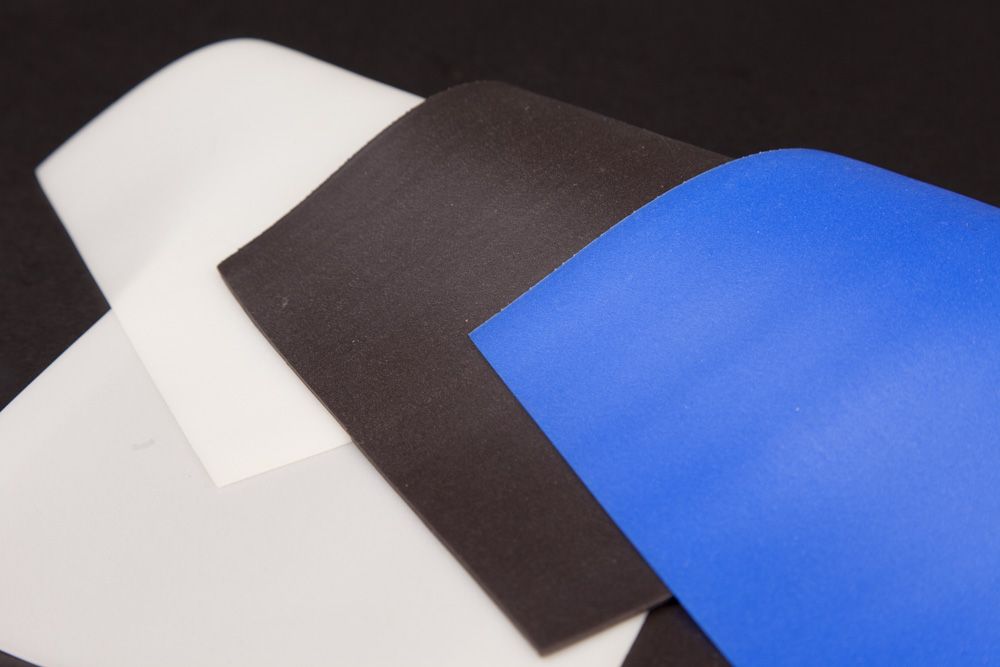

Custom Extruded Silicone Sheeting

We take pride in our ability to deliver a custom manufactured product to meet your specification requirements. Based on our extensive capabilities, nearly any design can be met. Below are strictly a few examples of profile types that ELBEX has the capability to produce. For more information please reference our capabilities page.

Standard translucent sheeting in various widths typically available for immediate shipment. For detailed pricing please see our silicone sheeting pricing page.

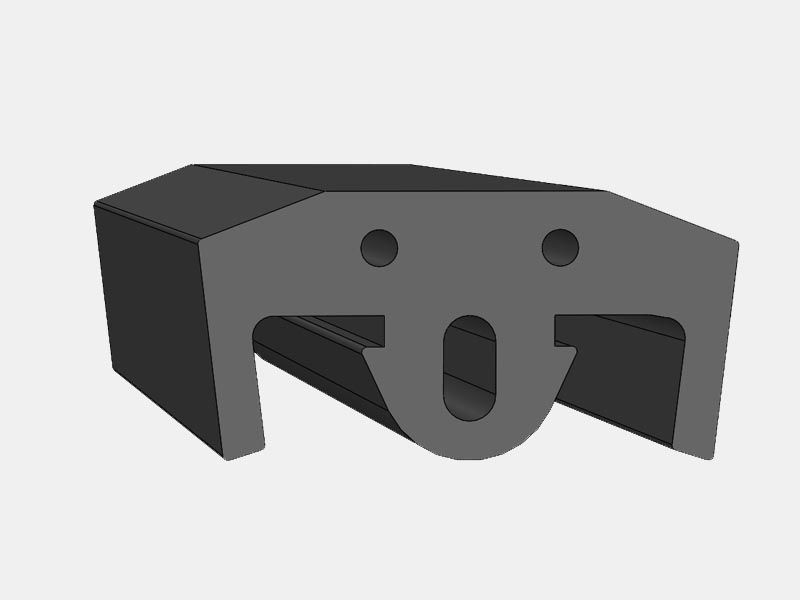

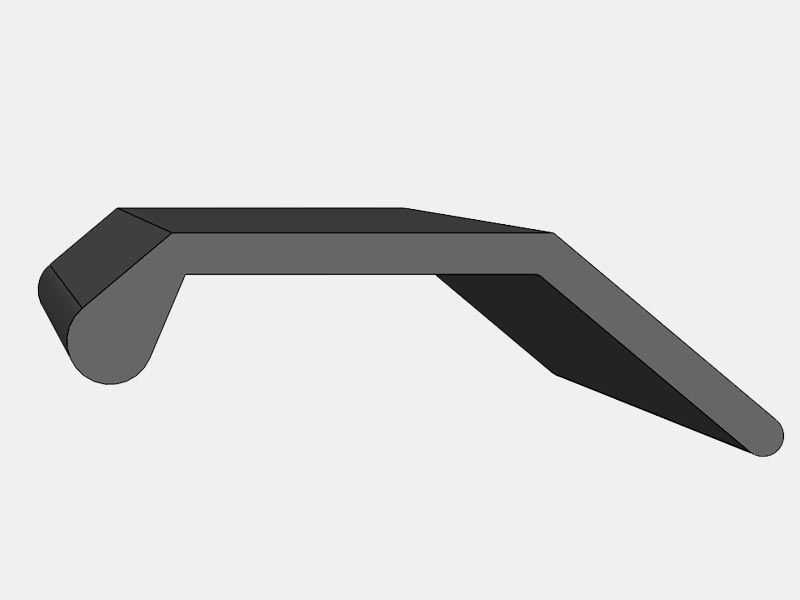

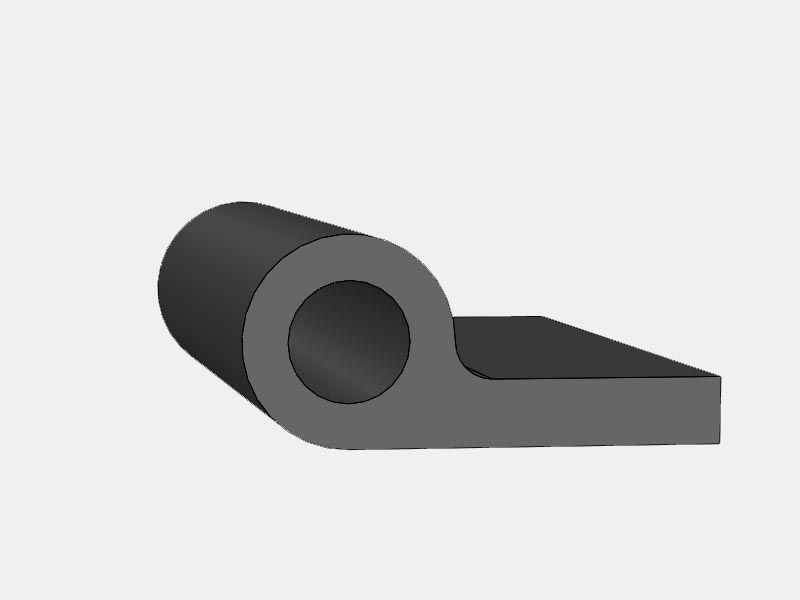

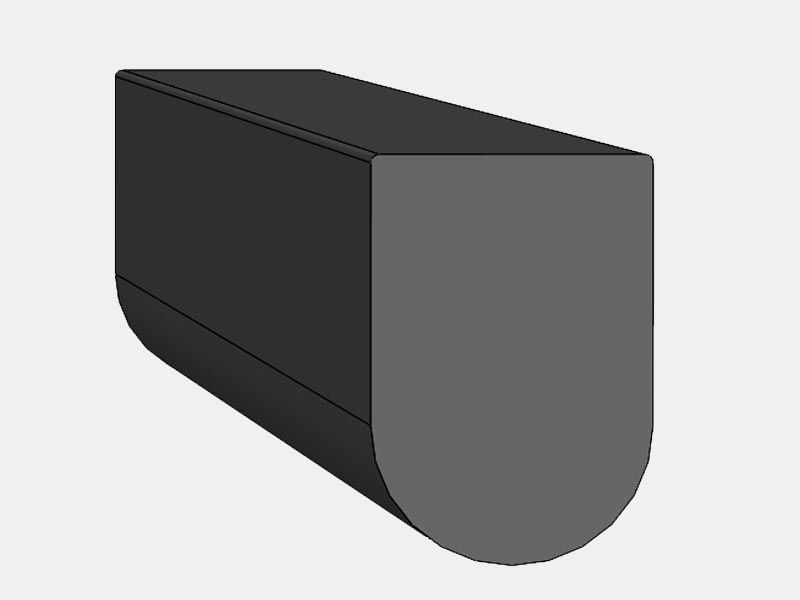

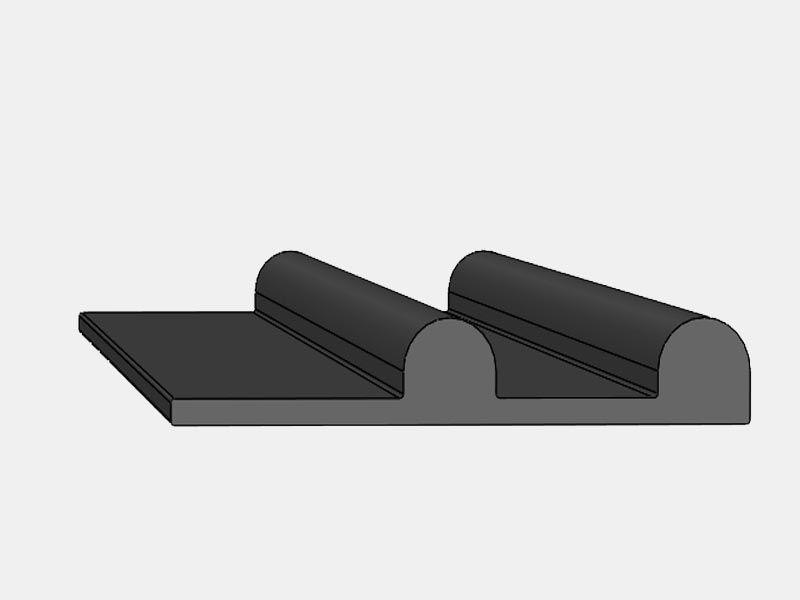

Custom Extruded Rubber

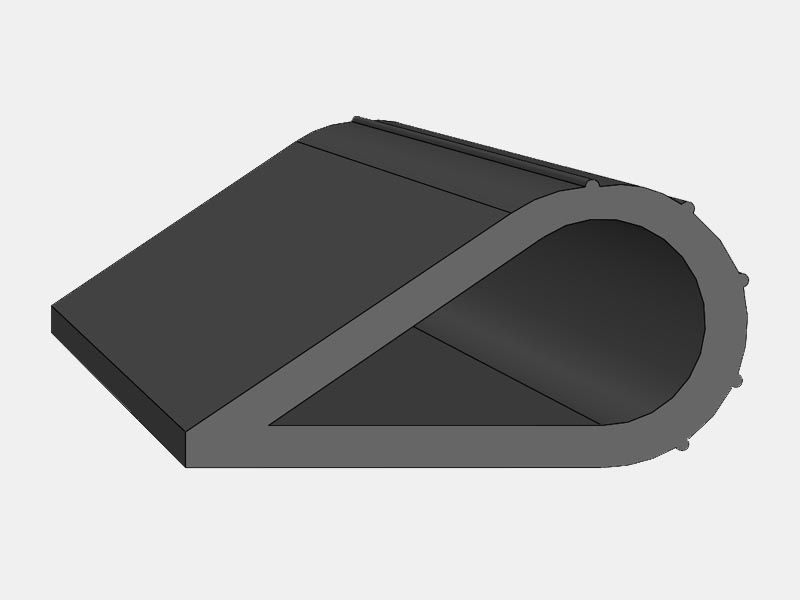

D-Sections

D-sections are used across many different industries and applications. They are used to fill voids and gaps, create a seal between two different surfaces, and provide vibration and noise control. Common uses are as weather seals and window and door seals. They often have pressure sensitive adhesive on the bottom of the profile to keep them stationary within the application.

Extruded rubber D-sections from ELBEX provide superior sealing and vibration and noise control because of our team that’s dedicated to quality through the entire extrusion manufacturing process.

All extrusions are available in continuous lengths and precise profile shapes, but can be cut to meet specific length requirements. Whatever your application, we can offer additional services such as vulcanized splicing, cutting, printing, and taping.

Please contact us to discuss your specific application needs.

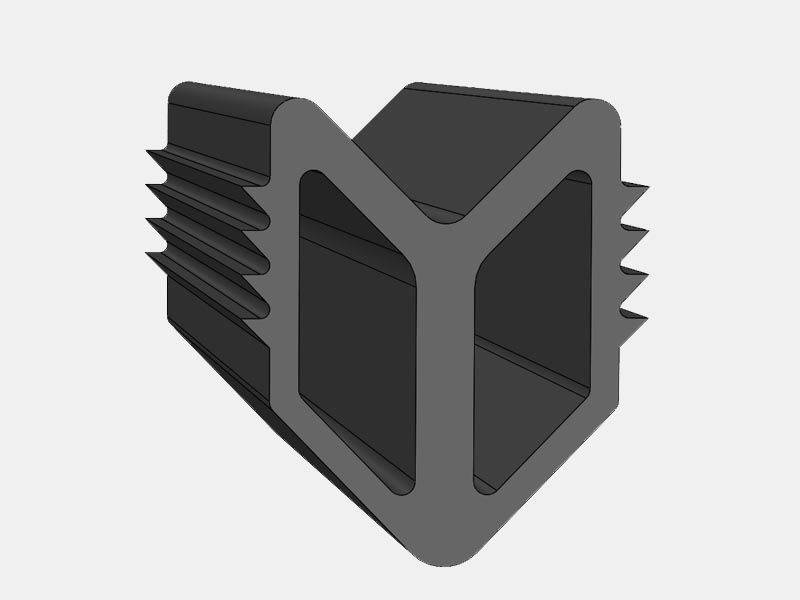

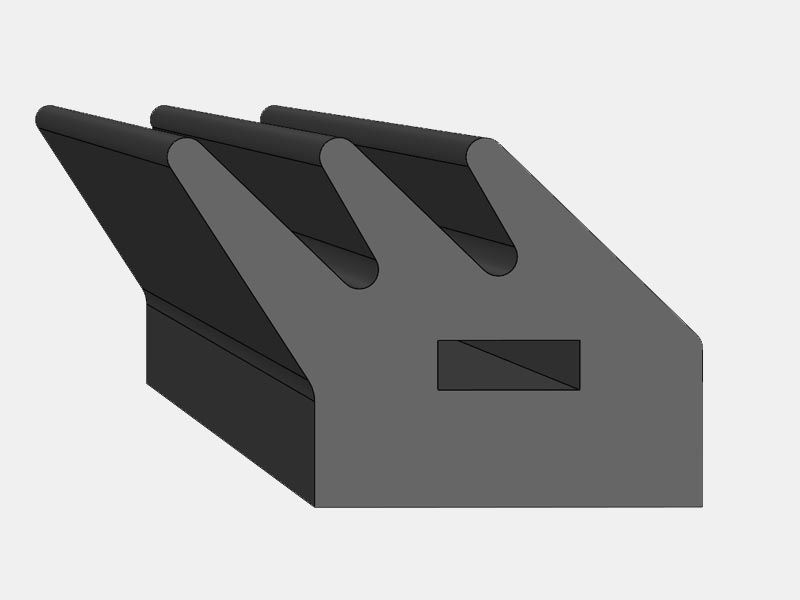

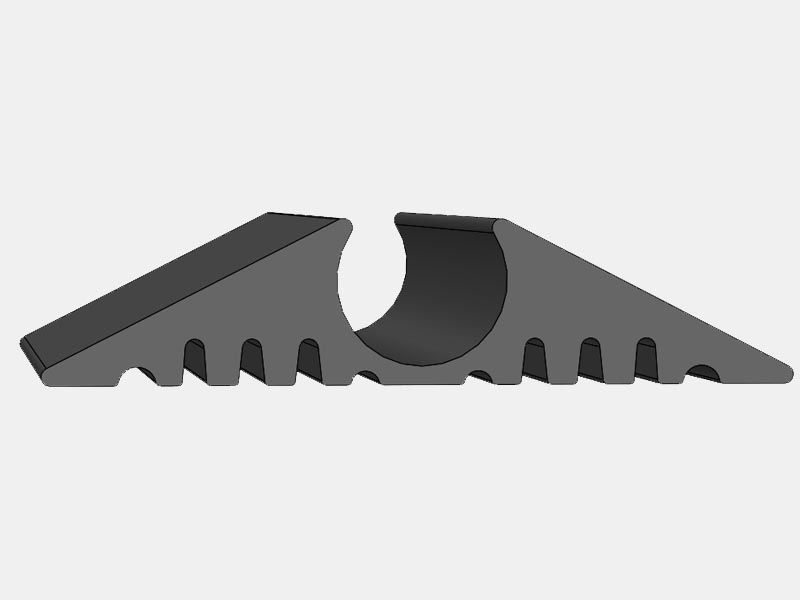

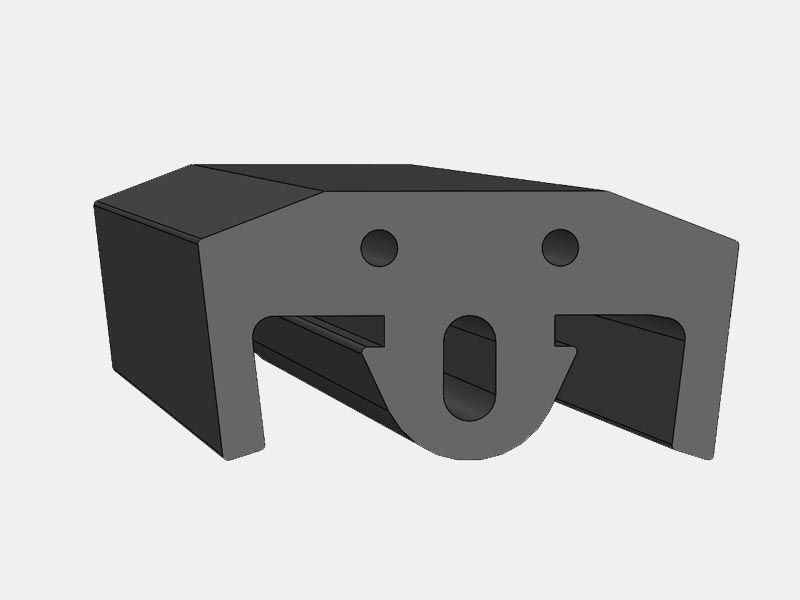

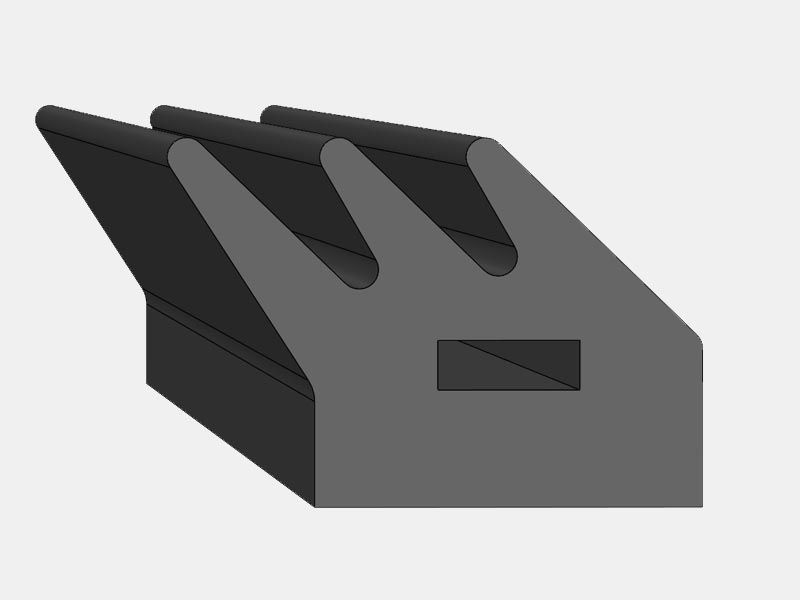

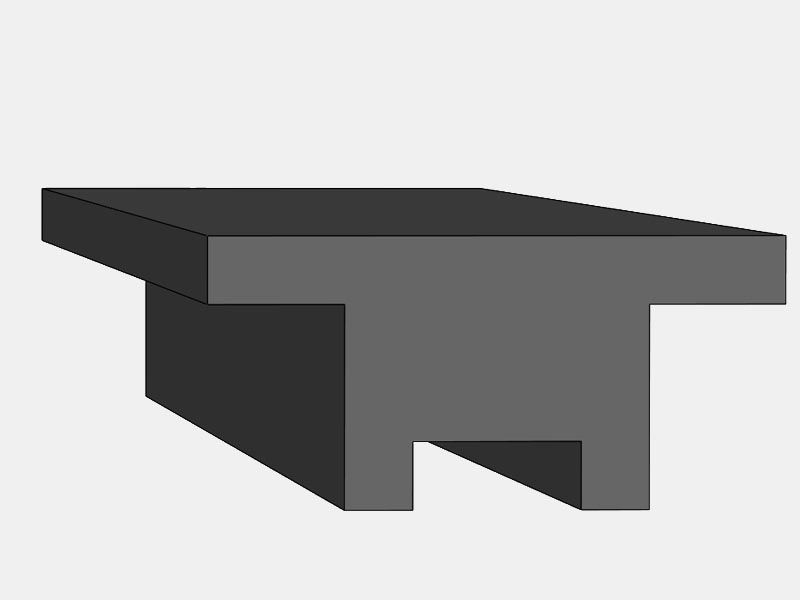

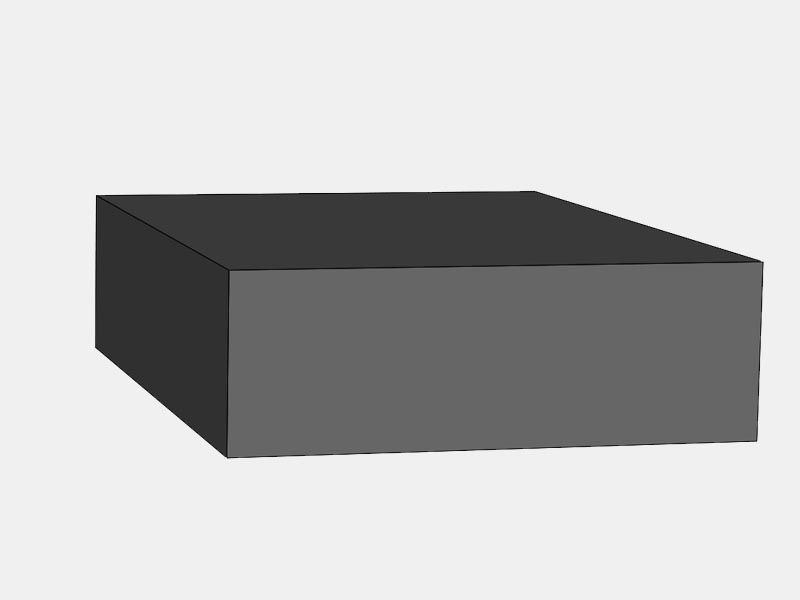

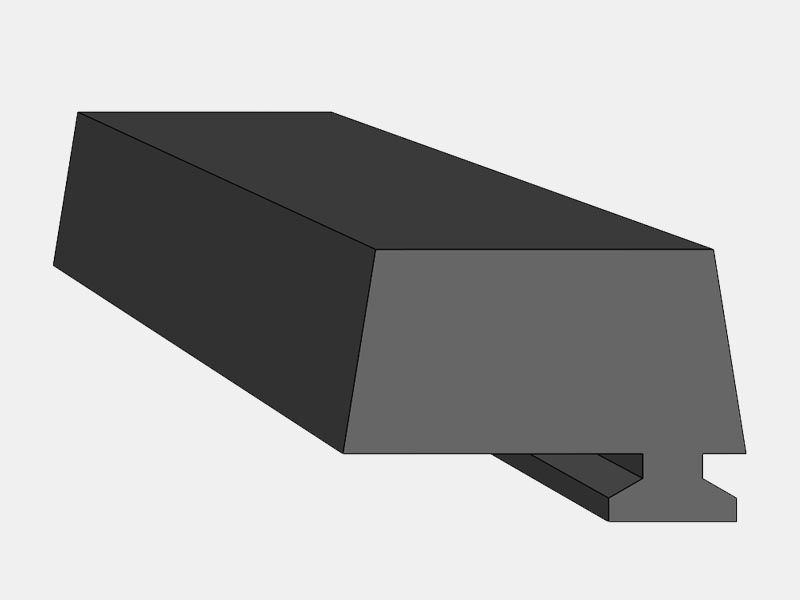

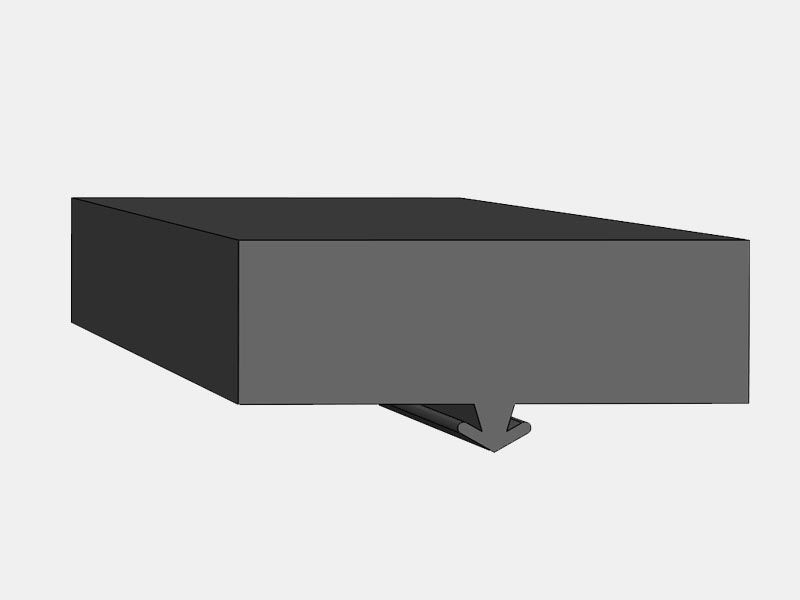

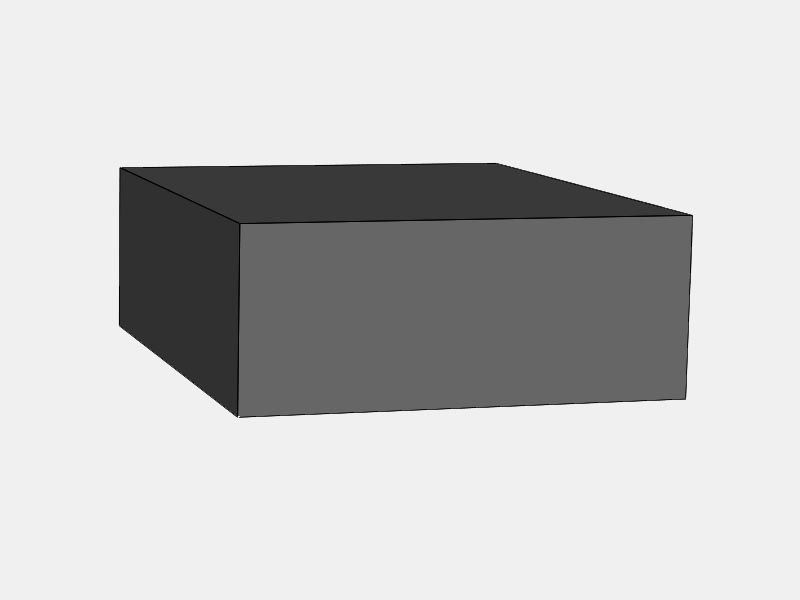

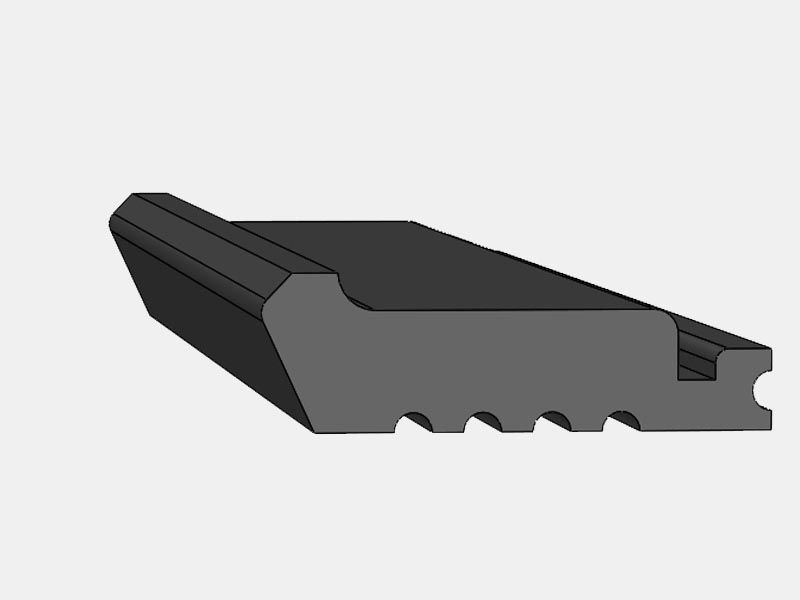

Setting Block Profiles

Product Description

The primary purpose of a setting block is to position and seat separate materials. They assist in dampening vibration and to minimize uneven surfaces. They are very commonly used in glazing applications to set glass within an aluminum channel. They range from very simple rectangular shapes to more complicated profiles that are designed to track into a channel.

Custom Design Available

We take pride in our ability to deliver a custom manufactured product to meet your specification requirements. Based on our extensive capabilities, nearly any design can be met. Below are strictly a few examples of profile types that ELBEX has the capability to produce. For more information please reference our capabilities page.

NOTE: Because many of our orders are custom orders, we do not carry an inventory. Please call one of our Sales Representatives to inquire into the item you are interested in.

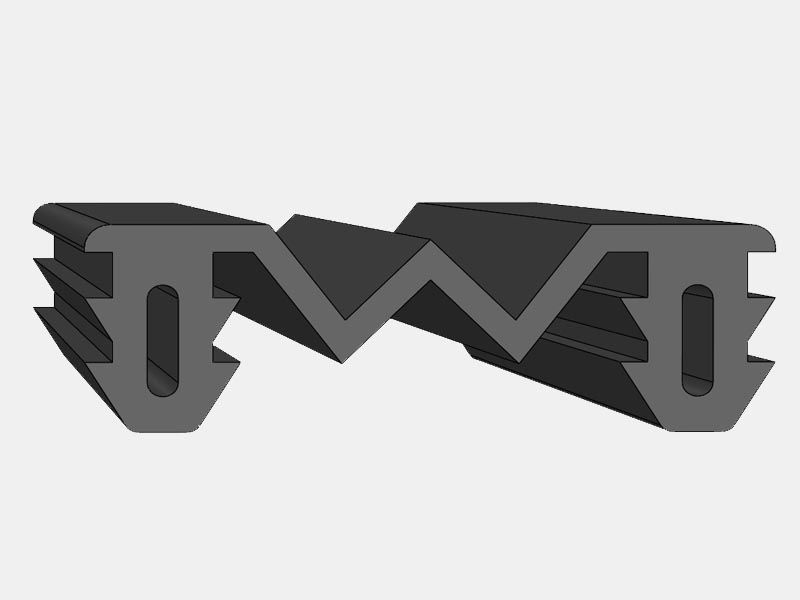

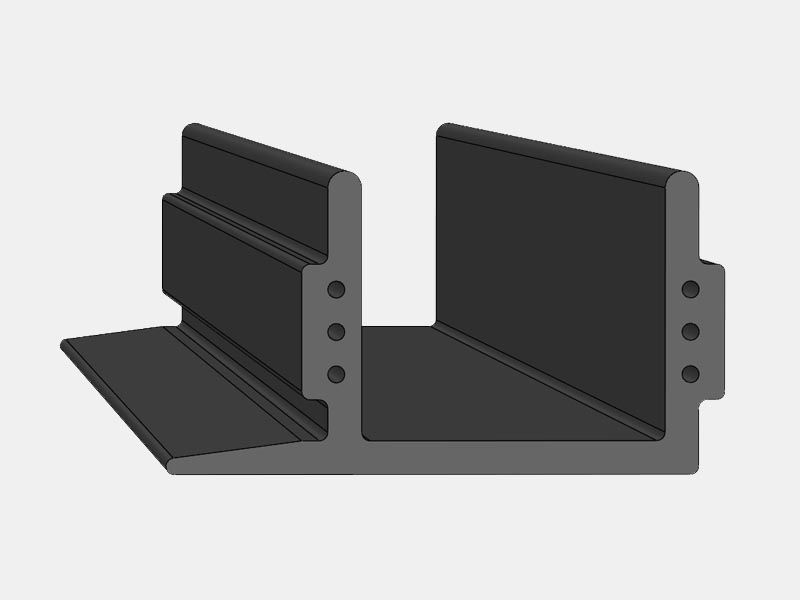

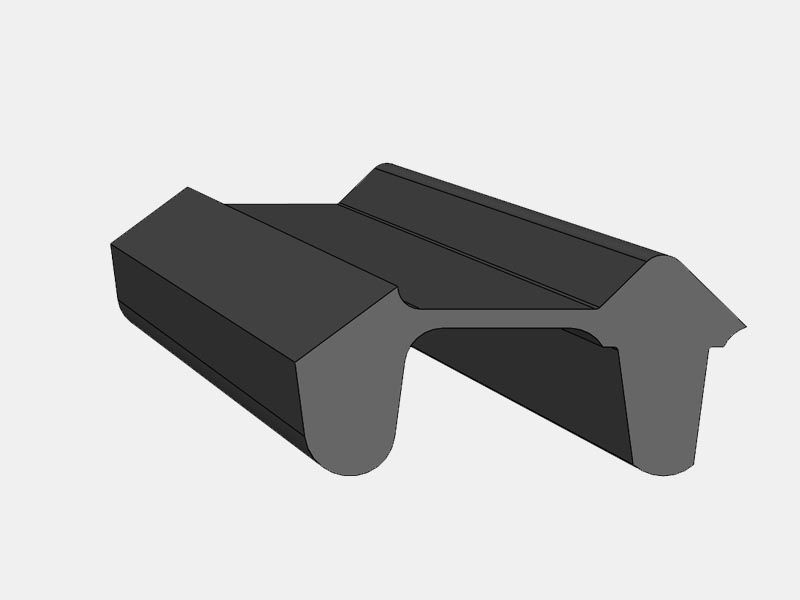

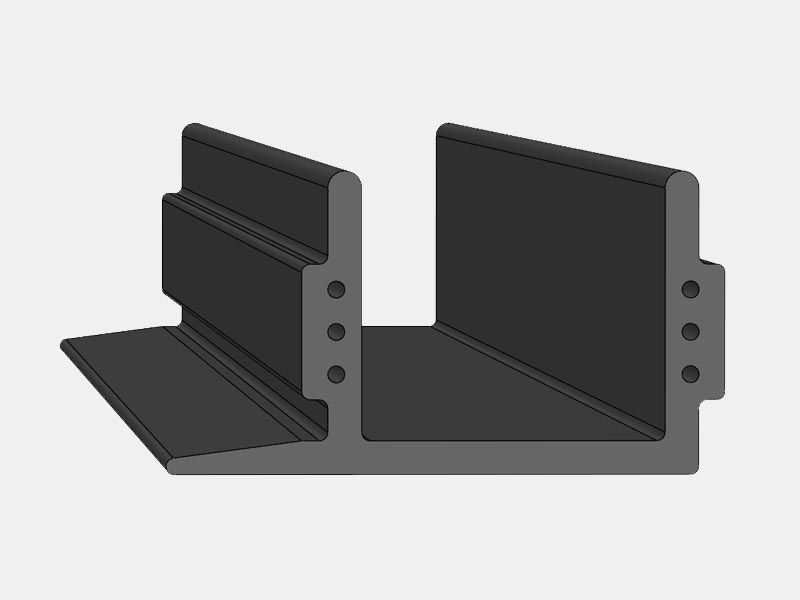

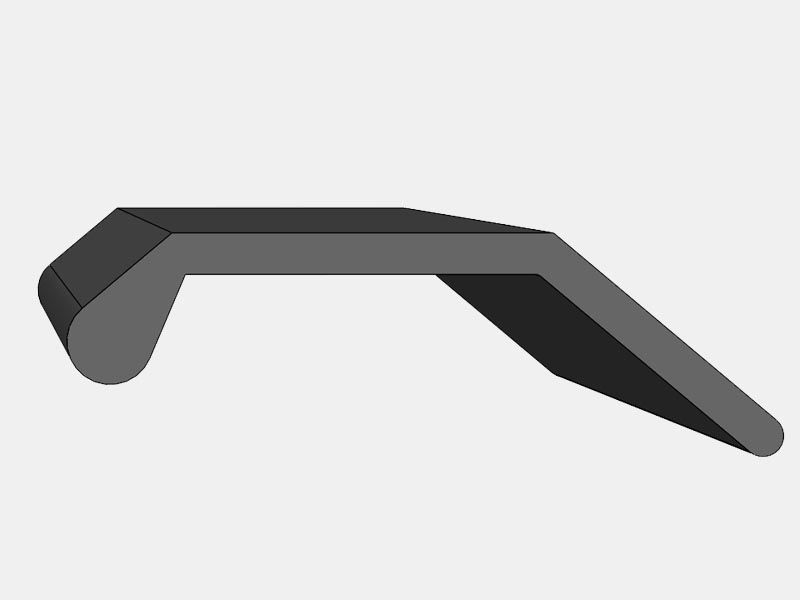

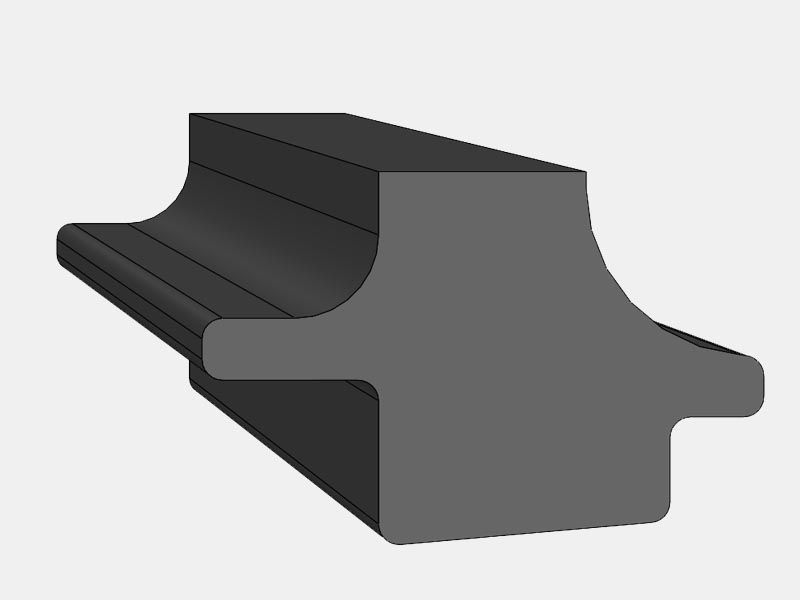

U-Channel Profile

Product Description

U-Shaped profiles are generally used to fit within a channel and serve as an edge guard to a mating piece. Their main purpose is to create a secure fit, eliminate vibration, and eliminate movement. Depending on application and exposure to conditions, they can be manufactured from a variety of material.

Custom Design Avaliable

We take pride in our ability to deliver a custom manufactured product to meet your specification requirements. Based on our extensive capabilities, nearly any design can be met. Below are strictly a few examples of profile types that ELBEX has the capability to produce. For more information please reference our capabilities page.

NOTE: Because many of our orders are custom orders, we do not carry an inventory. Please call one of our Sales Representatives to inquire into the item you are interested in.

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

CUSTOM ON-SITE TOOLING

We meet our customers’ needs for unique custom extrusions with in-house, custom tool and die design services.

TECHNICAL RESOURCES

We offer several technical resources and PDFs to assist in the design of effective and efficient rubber extrusions.

DESIGN ASSISTANCE

We evaluate your unique application need and are prepared to offer design assistance and troubleshoot previous issues as needed.