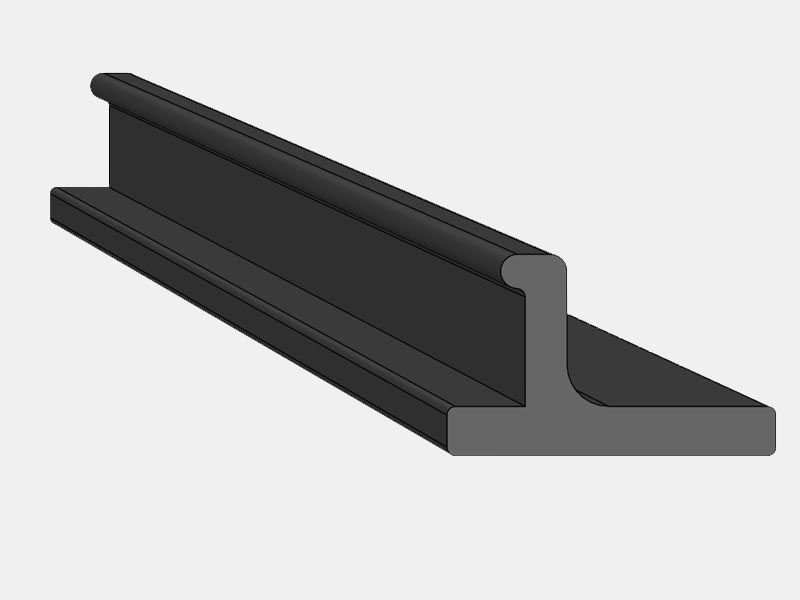

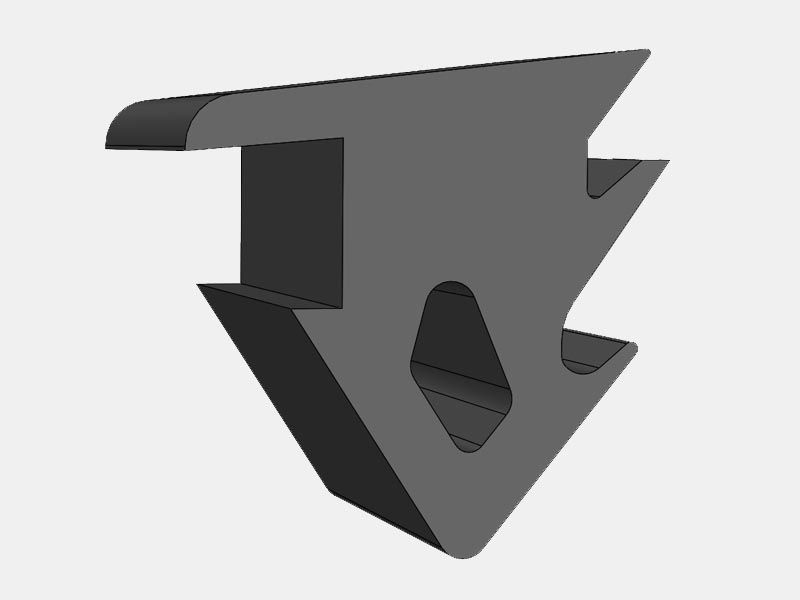

Extruded Rubber Glazing Systems

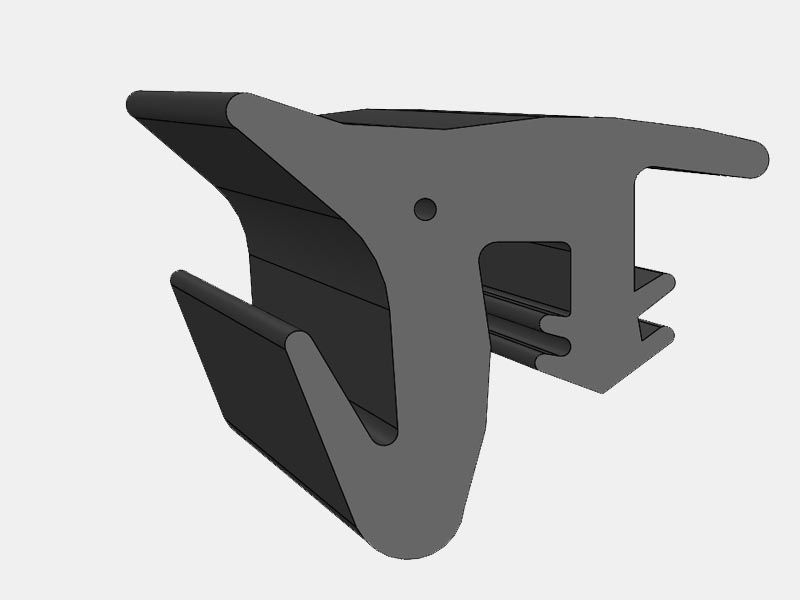

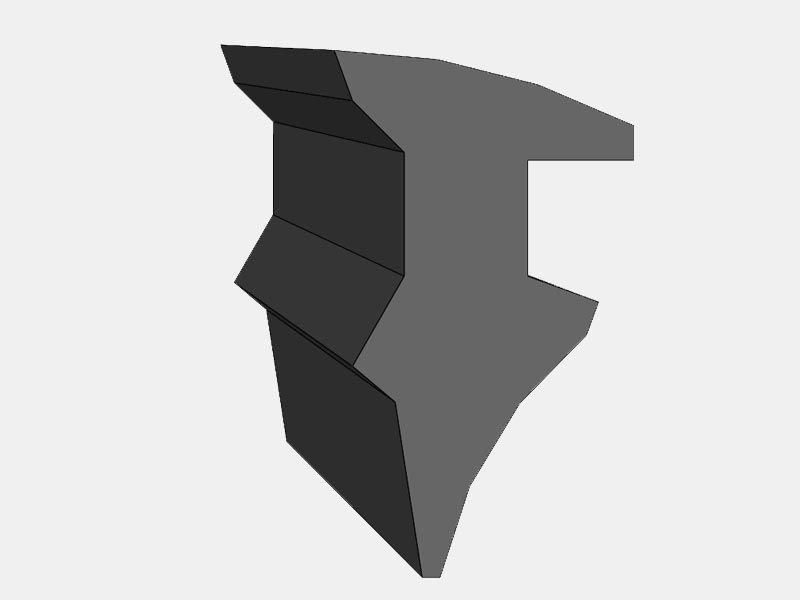

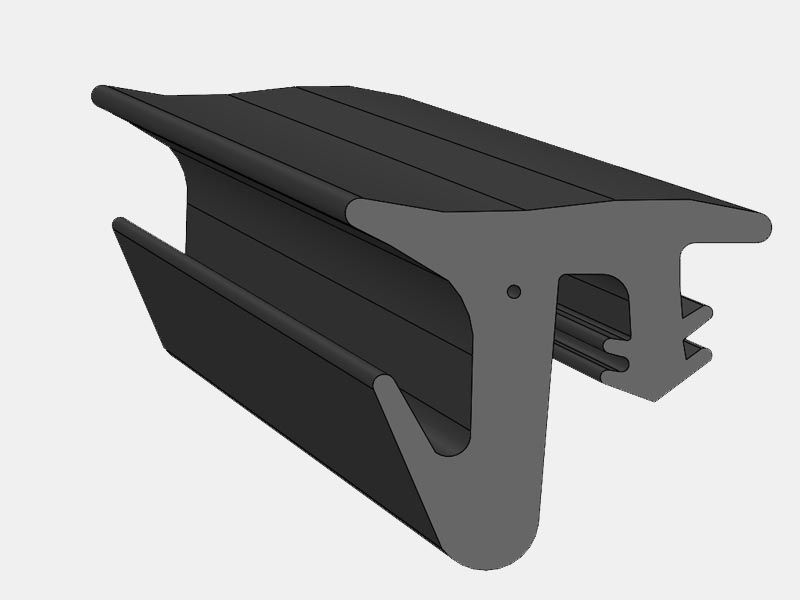

Extruded rubber glazing systems from ELBEX are molds used to set materials, create environmental barriers, reduce vibration or fill voids between two surfaces. These gaskets act as seals designed to keep air, water, and sound from leaking in or out of the applied static areas. In the case of windows, the rubber glazing systems wrap the glass, molding to the surface to create an extra tight seal between two areas. Extruded rubber glazing systems from ELBEX offer maximum performance and reliability.

Glazing System Applications

At ELBEX, we can create a custom glazing system to meet your unique application needs. We have extensive experience serving the following industries and more!

- Architectural - The most common application for rubber glazing systems in the architecture industry are for creating weather stripping insulation. With this use case there are many different types of gaskets that can be produced, depending on whether windows or doors are on the interior or exterior of the building. For either application, it is important to note what kind of ratings are needed for fire, sound, water, air, etc. These glazing systems can be applied across commercial or residential buildings, providing environmental barriers and a proper fit for doors and windows.

- Indoor Agriculture - It’s imperative that growers keep plants and crops free of contaminants. Rubber glazing systems installed within indoor grow facilities means having an air-tight barrier between the grow rooms and the rest of the facility. These systems should be applied to seal any doors and windows surrounding any rooms containing plants, keeping them free of pests and particulates.

- Automotive - ELBEX extruded rubber glazing systems are an ideal fit for production of spare tire no-rattle pads, hinge covers, acoustic covers, gaskets, and more. They are also great for securing windows to cars, as our systems are manufactured to withstand the elements of mother nature.

- Marine - Rubber glazing systems for this industry are a vital part of extending the life of boats, as these gaskets can protect against serious leaks and flooding.

Please contact us to discuss your specific application needs.

Custom Rubber Glazing Systems

As designated by our accreditation of the ISO 9001:2015 without Design certification, we offer reassurance to our customers that ELBEX provides top quality extrusions, including extruded rubber glazing systems that are purpose-built for their specific needs.

The ISO International Standards ensure that products and services being made by companies in a variety of industries around the world are safe, reliable and of good quality. With our main focus being on custom design manufacturing, we’ve carried out work across many industries, so you can trust that you are dealing with very experienced and knowledgeable engineers. We will help you with material selection, provide custom tool and die design services, and collaborate with you throughout the design process.

Engineering Resources to

Support Your Project

ELBEX Corporation is committed to providing top-notch support to its customers during the design and manufacturing process. We understand that the success of our clients is directly tied to our ability to provide them with the highest level of service possible. Therefore, we work closely with our customers to ensure that their needs are fully understood and met. Our team of experts has a wealth of experience in the industry, which enables us to provide valuable insights and advice to our clients.

CUSTOM ON-SITE TOOLING

We meet our customers’ needs for unique custom extrusions with in-house, custom tool and die design services.

TECHNICAL RESOURCES

We offer several technical resources and PDFs to assist in the design of effective and efficient rubber extrusions.

DESIGN ASSISTANCE

We evaluate your unique application need and are prepared to offer design assistance and troubleshoot previous issues as needed.

Applications in the Manufacturing Industry

Our rubber extrusions play a vital role in the performance of a wide range of industrial and manufacturing systems. Our products can be manufactured to withstand extreme environments that manufacturing and industrial environments are subject to, including direct sunlight and dramatic changes in temperature that can cause expansion and contraction. Whether you need a rubber extrusion for a specific product you’re manufacturing, or for the actual factory building itself, our rubber extrusions fit the bill.

- Pipe ramps

- Glazing system profiles

- Silicone sheeting

- Expansion joints

Applications in the Architectural Industry

ELBEX can offer high quality, custom rubber extrusions to the architectural industry. Our engineers will work with you to find the right solution for your project, and choose materials that meet regulatory standards and building codes.

Our rubber extrusions are most commonly used in the architectural industry as environmental barriers, to fill voids between two surfaces, and to ensure a proper fit. Architects and building engineers must choose the right materials to ensure lasting structural integrity. Our engineers can work with you to select the right materials in regards to your specific project. Contact us today to let us know what you need for your project!

- Air and water barriers for windows and doors

- Glazing system profiles used to seat and seal architectural facades and fenestration systems

- Setting blocks