Learning About the D-Section Profile

With more than 25 years of experience within the extrusion industry, ELBEX Corporation is an ISO Certified leader in rubber and silicone extrusions manufacturing. Our in-depth level of project planning and unique manufacturing capabilities coupled with the strong relationships cultivated with suppliers and vendors set us apart from other extrusions manufactures.

Our manufacturing capabilities include the ability to produce a wide range of profile designs in both dense and sponge materials, enabling us to produce products that meet your projects unique requirements.

We manufacture a wide range of extrusion profiles for a variety of markets, including automotive, construction, mass transit, water control, and many more. Our team has the experience and manufacturing prowess to ensure your extrusions meet or exceed the demand you place on them.

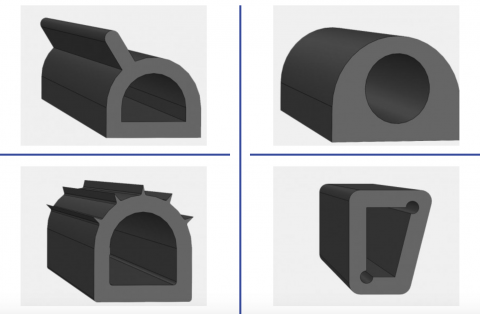

One of our multiple profile sections is the D-Section profile. Its name is derived from its resemblance to the letter “D” in a cross-sectional view of the profile.

The D-Section is a profile used to fill voids and gaps across multiple applications and markets. Common applications of D-Section profiles are as weather seals on doors and windows. D-Section profiles can also create a seal between two different surfaces. To keep them in place, D-Section profiles typically have a pressure-sensitive adhesive on the bottom of the profile.

At ELBEX, we can manufacture standard D-Section profiles or create customized D-Section products based on your specific needs.

Some of the more common applications include:

- Pipe ramps

- Silicone sheeting

- Expansion joints

- Gaskets

- Hinge Covers

- Door and window seals

- Cushion for components

- Weatherstripping

- Glazing

- Edge trim

- Door and window seals

- Expansion joints

Contact the expert team at ELBEX today! We can walk through your project needs and help you find a solution that will meet your unique requirements.