The Importance of Quality Control & Testing With Rubber Extrusions

Rubber extrusions are used in a wide variety of applications, from automotive and aerospace to water control and construction. Regardless of the exact usage requirements, quality control is essential for ensuring that every extrusion will fulfill its role effectively.

Importance of Quality Control

Quality control isn’t just a matter of meeting expectations. Rubber extrusions play vital roles that can significantly affect the performance, durability, and safety of a finished application. An effective quality control program ensures that the finished products live up to material requirements and design specifications. This prevents accidents and damages, providing lasting quality for the finished application.

Of course, strong quality control efforts also reduce waste, speed up production, and lower costs by preventing downtime, the need to “re-do” an order, and other issues. Strong quality control ultimately benefits everyone.

Ensuring Quality Through Testing

In the rubber extrusion manufacturing process, quality control testing occurs at several different stages to ensure the finished products meet expectations. This starts by inspecting incoming raw materials to ensure their quality and provide complete traceability if an issue occurs. SPC inspections during manufacturing control the quality of production processes, while testing and inspections after manufacturing is complete will help ensure that the finished extrusions meet performance demands.

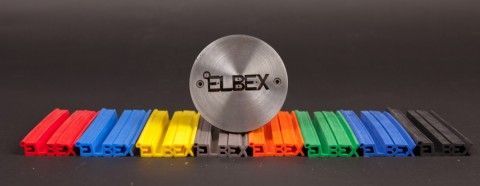

At Elbex, our team is committed to high-level quality control from start to finish. Our ISO certified quality system ensures that our finished products will meet and exceed your expectations. Our manufacturing can meet ASTM, SAE, AMS, military, and RMA specifications to ensure superior performance. To learn more or to request a quote, contact us today.